噴涂機器人工藝

發布時間 : 2021-08-31 瀏覽次數 : 次噴涂機器人可以安(an)全高效(xiao)(xiao)地(di)完成(cheng)各(ge)種(zhong)噴涂作業,可以幫(bang)助企業有(you)效(xiao)(xiao)地(di)節約飆升的人工成(cheng)本,并在一定(ding)程(cheng)度上緩解(jie)就業問題。

隨著智能(neng)技術(shu)的(de)快速發展(zhan),噴(pen)涂(tu)機器(qi)人被廣泛應用于各行各業。噴(pen)涂(tu)機器(qi)人工藝(yi)的(de)噴(pen)涂(tu)方法(fa)在噴(pen)涂(tu)技術(shu)適用于噴(pen)涂(tu)的(de)產品上有所不同(tong)。

1、空(kong)(kong)(kong)氣(qi)噴涂(tu)法:噴涂(tu)機器(qi)人的(de)空(kong)(kong)(kong)氣(qi)噴涂(tu)法主要是利用(yong)(yong)(yong)壓(ya)縮空(kong)(kong)(kong)氣(qi)流流經噴槍的(de)噴嘴孔(kong)后形成(cheng)負壓(ya),然(ran)后在負壓(ya)的(de)作用(yong)(yong)(yong)下,涂(tu)層(ceng)被噴槍吸入(ru)并噴涂(tu),使霧(wu)化后的(de)涂(tu)層(ceng)均勻地噴灑在工件(jian)表(biao)面,形成(cheng)光滑的(de)涂(tu)層(ceng)。噴涂(tu)機器(qi)人的(de)空(kong)(kong)(kong)氣(qi)噴涂(tu)方(fang)法一般用(yong)(yong)(yong)于噴涂(tu)家具、電子外(wai)殼等工件(jian)。由于空(kong)(kong)(kong)氣(qi)噴涂(tu)法生產成(cheng)本低,在噴涂(tu)機器(qi)人的(de)三種(zhong)噴涂(tu)方(fang)法中得到廣泛應(ying)用(yong)(yong)(yong)。

2、高(gao)壓(ya)(ya)無氣(qi)噴(pen)(pen)(pen)(pen)涂(tu)(tu)(tu)法(fa):與(yu)空氣(qi)噴(pen)(pen)(pen)(pen)涂(tu)(tu)(tu)法(fa)相比,噴(pen)(pen)(pen)(pen)涂(tu)(tu)(tu)機器人(ren)的(de)高(gao)壓(ya)(ya)無氣(qi)噴(pen)(pen)(pen)(pen)涂(tu)(tu)(tu)法(fa)是(shi)(shi)一(yi)種先進的(de)噴(pen)(pen)(pen)(pen)涂(tu)(tu)(tu)方(fang)法(fa),主要是(shi)(shi)通(tong)(tong)過增(zeng)壓(ya)(ya)泵將涂(tu)(tu)(tu)層加壓(ya)(ya),然后通(tong)(tong)過噴(pen)(pen)(pen)(pen)槍的(de)細孔將涂(tu)(tu)(tu)層霧化(hua)。高(gao)壓(ya)(ya)無氣(qi)噴(pen)(pen)(pen)(pen)涂(tu)(tu)(tu)法(fa)涂(tu)(tu)(tu)層利用(yong)率高(gao),噴(pen)(pen)(pen)(pen)涂(tu)(tu)(tu)生產效率高(gao),噴(pen)(pen)(pen)(pen)涂(tu)(tu)(tu)機器人(ren)采用(yong)高(gao)壓(ya)(ya)無氣(qi)噴(pen)(pen)(pen)(pen)涂(tu)(tu)(tu)法(fa)噴(pen)(pen)(pen)(pen)涂(tu)(tu)(tu)的(de)工(gong)件質(zhi)量(liang)明顯優于空氣(qi)噴(pen)(pen)(pen)(pen)涂(tu)(tu)(tu)法(fa)。高(gao)壓(ya)(ya)無氣(qi)噴(pen)(pen)(pen)(pen)涂(tu)(tu)(tu)通(tong)(tong)常(chang)適(shi)用(yong)于噴(pen)(pen)(pen)(pen)涂(tu)(tu)(tu)涂(tu)(tu)(tu)層質(zhi)量(liang)要求高(gao)的(de)工(gong)件

3、靜(jing)電(dian)噴(pen)涂(tu)(tu)(tu)(tu):在三(san)種噴(pen)涂(tu)(tu)(tu)(tu)方(fang)法(fa)中,靜(jing)電(dian)噴(pen)涂(tu)(tu)(tu)(tu)是噴(pen)涂(tu)(tu)(tu)(tu)機器人使用(yong)很廣泛的(de)(de)噴(pen)涂(tu)(tu)(tu)(tu)方(fang)法(fa)。其噴(pen)涂(tu)(tu)(tu)(tu)原理是將接(jie)(jie)地的(de)(de)待噴(pen)涂(tu)(tu)(tu)(tu)工件作為陽極,涂(tu)(tu)(tu)(tu)層霧(wu)化(hua)器連接(jie)(jie)負高(gao)壓作為陰極,使霧(wu)化(hua)后的(de)(de)涂(tu)(tu)(tu)(tu)層顆粒通過靜(jing)電(dian)作用(yong)帶(dai)電(dian)吸(xi)附在工件表面(mian)。噴(pen)涂(tu)(tu)(tu)(tu)機器人采用(yong)的(de)(de)靜(jing)電(dian)噴(pen)涂(tu)(tu)(tu)(tu)方(fang)法(fa)常用(yong)于金(jin)屬噴(pen)涂(tu)(tu)(tu)(tu)或涂(tu)(tu)(tu)(tu)層結構復(fu)雜的(de)(de)工件噴(pen)涂(tu)(tu)(tu)(tu)。

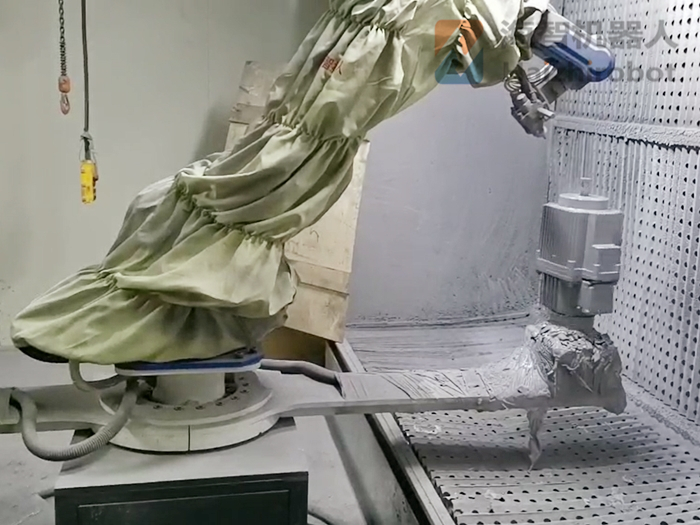

噴(pen)涂機器人主要(yao)包含三部分:機(ji)器人(ren)本體、機(ji)器人(ren)噴(pen)(pen)涂系統和(he)(he)噴(pen)(pen)涂控(kong)(kong)(kong)制系統。噴(pen)(pen)涂控(kong)(kong)(kong)制系統包含了空氣(qi)壓力(li)模擬量控(kong)(kong)(kong)制、流(liu)量輸(shu)出(chu)模擬量控(kong)(kong)(kong)制和(he)(he)開(kai)槍(qiang)信號控(kong)(kong)(kong)制等。與傳統的(de)機(ji)械噴(pen)(pen)涂相比,使用噴(pen)(pen)涂機(ji)器人(ren)可以有(you)效降低人(ren)工噴(pen)(pen)涂的(de)勞(lao)動(dong)強(qiang)度(du),解決了人(ren)為噴(pen)(pen)涂厚度(du)不均和(he)(he)情(qing)緒不穩定的(de)問題。

噴(pen)涂機器人(ren)工(gong)(gong)藝流程包含:上輸送鏈——自動除(chu)(chu)塵室—預熱除(chu)(chu)濕(shi)—機器人(ren)噴(pen)涂—流平(ping)—烘干—冷卻—下(xia)件(常(chang)規噴(pen)涂機器人(ren)工(gong)(gong)藝自動化生(sheng)產(chan)線(xian),大(da)部分需要結合實際的工(gong)(gong)件情況來確認)!

機器人噴涂工藝包:在機器人控制系統里面一般專用于一個行業(ye)的控制系統都會具(ju)有工藝包,它可以有效節省(sheng)噴涂編程動作,節省(sheng)時間,方便(bian)操作。