數控車床機械手臂

發布時間 : 2021-09-16 瀏覽次數 : 次數控(kong)車床機械手(shou)(shou)臂是選用合適(shi)機型(xing)的關節工(gong)(gong)(gong)業(ye)(ye)(ye)機器人,搭配(pei)原有車床或(huo)新車床的使用,它(ta)們的合作(zuo)可以讓生產(chan)實現自動化生產(chan),機械手(shou)(shou)臂將(jiang)工(gong)(gong)(gong)件從車床已加(jia)(jia)(jia)工(gong)(gong)(gong)位置(zhi)取下(xia)后放(fang)入未加(jia)(jia)(jia)工(gong)(gong)(gong)的工(gong)(gong)(gong)件,從而代替員工(gong)(gong)(gong)進(jin)行作(zuo)業(ye)(ye)(ye),數控(kong)類機床均可配(pei)套(tao)工(gong)(gong)(gong)業(ye)(ye)(ye)機械手(shou)(shou)臂來(lai)實現該動作(zuo),代替人工(gong)(gong)(gong),為(wei)企業(ye)(ye)(ye)節省(sheng)用人成本(ben),增加(jia)(jia)(jia)品質效果,方便(bian)生產(chan)管理等。

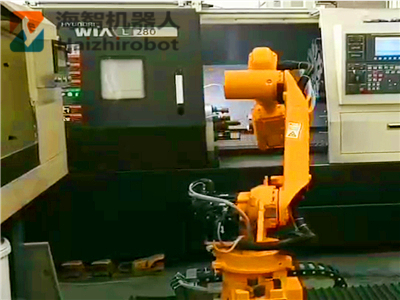

下圖案例是海智機器人做的機械手臂一控二數控車床應用案例,其選用海智HZ系列六軸機器人,下面詳細節省一下!

數控車床機械臂(機械手,機械手臂,工業機器人均為統稱)案例說明!

工件(jian)來(lai)料方式:上圖案例(li)是(shi)小件(jian)圓盤類五金,采用了分(fen)(fen)度盤定位(wei)頂升(sheng)機構,是(shi)海智(zhi)機器人定制類型,工件(jian)可以(yi)一(yi)次(ci)放入待(dai)加工工件(jian)150件(jian),工件(jian)在(zai)機械手(shou)(shou)臂取(qu)(qu)料后會進行(xing)自動頂升(sheng),讓(rang)每次(ci)機械手(shou)(shou)臂抓取(qu)(qu)工件(jian)時都在(zai)統(tong)一(yi)位(wei)置,而(er)抓取(qu)(qu)完成這(zhe)一(yi)摞則通(tong)過分(fen)(fen)度方式旋轉,進行(xing)頂升(sheng)取(qu)(qu)料;

數控車(che)床(chuang)換料方式:車(che)床(chuang)內容如在加工(gong)的(de)時候(hou),機械手臂在來料位(wei)置先行取料,再到車(che)床(chuang)等待加工(gong)完成后的(de)下料以(yi)及剛剛取料工(gong)件的(de)上料,工(gong)件的(de)取料和放料會在一(yi)(yi)同(tong)完成,工(gong)業機器人(ren)末(mo)端的(de)工(gong)件治具海智定(ding)制(zhi)了專用(yong)的(de)雙頭(tou)(tou)夾(jia)爪,一(yi)(yi)頭(tou)(tou)取料一(yi)(yi)頭(tou)(tou)放料;

六軸機械手(shou)數控車床機(ji)型:車床為客戶(hu)原有集成改造和(he)工業機(ji)械(xie)手(shou)通(tong)訊聯(lian)機(ji)使用,而六(liu)軸機(ji)械(xie)手(shou)則(ze)是海智機(ji)器(qi)人HZ1510-6機(ji)型;

數控(kong)(kong)車床機(ji)械手(shou)臂機(ji)型參(can)數:活動半徑1.5M、負載6KG、控(kong)(kong)制方式一(yi)拖(tuo)二形式,是指一(yi)臺(tai)工業機(ji)械手(shou)臂控(kong)(kong)制兩(liang)臺(tai)數控(kong)(kong)機(ji)床的上下(xia)料工作;

海智機器人數控車床機械手臂自動上下料應用案例(li)展示(其(qi)它案例(li)):

東莞市(shi)海智機(ji)器(qi)人自動(dong)化科技有限公司:數控車床(chuang)機(ji)(ji)械手臂選用(yong)機(ji)(ji)型需要(yao)結(jie)合工(gong)件的尺寸,重量,機(ji)(ji)床(chuang)空間(jian),機(ji)(ji)床(chuang)類型,加工(gong)單雙頭(tou)以(yi)及(ji)加工(gong)節拍,夾(jia)(jia)頭(tou)是(shi)否具(ju)有(you)自動夾(jia)(jia)緊(jin)功能等信(xin)息(xi)來(lai)評估(gu),無論是(shi)手動夾(jia)(jia)緊(jin)機(ji)(ji)床(chuang)或者自動海智(zhi)都(dou)可以(yi)完成改造(zao),海智(zhi)機(ji)(ji)器人具(ju)有(you)非常豐(feng)富的機(ji)(ji)床(chuang)上下料機(ji)(ji)器人應用(yong)經驗,更是(shi)一家工(gong)業機(ji)(ji)器人生產廠家!歡迎咨詢溝(gou)通!