數控機床與工業機器人集成應用案例

發布時間 : 2021-04-09 瀏覽次數 : 次隨著(zhu)自動化(hua)需求的(de)提升,工(gong)業機(ji)器(qi)(qi)人(ren)(ren)應(ying)用(yong)得到(dao)更大(da)的(de)拓展,機(ji)器(qi)(qi)人(ren)(ren)在(zai)數控機(ji)床上下料、物料搬運碼垛、噴涂、焊接、沖壓、組(zu)裝裝配等領域(yu)也得到(dao)了(le)(le)廣泛應(ying)用(yong);傳統企業幾乎都采用(yong)人(ren)(ren)力(li)進行(xing)加(jia)工(gong)機(ji)床上下料,這種作業方式存在(zai)勞動強(qiang)度大(da)、產量和質量不穩定等弊端。在(zai)“以機(ji)換人(ren)(ren)”的(de)大(da)環(huan)境(jing)下,越(yue)(yue)來(lai)越(yue)(yue)多(duo)的(de)企業工(gong)廠采用(yong)工(gong)業機(ji)器(qi)(qi)人(ren)(ren)代替(ti)人(ren)(ren)工(gong)進行(xing)噴涂、搬運、上下料等應(ying)用(yong),降低了(le)(le)人(ren)(ren)力(li)成本,同時提高了(le)(le)產量和品質,提升了(le)(le)企業的(de)競爭力(li)。

工業機器人與數控機床集成應用常見四大案例包括:數控沖床機械手、數控車床機械手、折彎機床機械手以及鍛壓機械手等集成應用,這些是屬于上下料機器人應用領域較為常見的工業機器人、數控機床機械手集成應用,下面海智逐步講解!

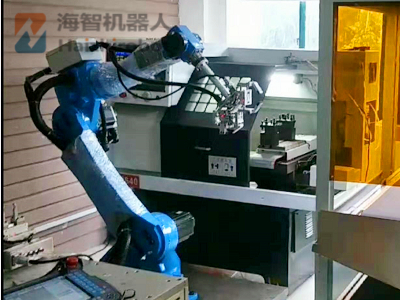

1、數控車(che)床機(ji)器人集(ji)成應用

車(che)床加(jia)(jia)(jia)工(gong)(gong)(gong)是五金金屬材(cai)料(liao)常見的加(jia)(jia)(jia)工(gong)(gong)(gong)設(she)備通常需要人工(gong)(gong)(gong)將產(chan)品上料(liao)下料(liao),而車(che)床機械手可以(yi)代替(ti)人工(gong)(gong)(gong)實(shi)現(xian)自動化(hua)(hua)上下料(liao),常見有1托(tuo)二數控車(che)床、1托(tuo)三、1托(tuo)四等海(hai)智機器人還做1托(tuo)八的車(che)床,是可以(yi)將幾臺機床連(lian)續加(jia)(jia)(jia)工(gong)(gong)(gong)工(gong)(gong)(gong)件的一種數控機床自動化(hua)(hua)應用。

2、數控沖床機械手集成應用

機械手與壓(ya)(ya)(ya)力成(cheng)型機(ji)(ji)沖(chong)(chong)(chong)壓(ya)(ya)(ya)集成(cheng)應(ying)用(yong)常見的兩種方式;其一是(shi)單臺(tai)(tai)機(ji)(ji)械手(shou)沖(chong)(chong)(chong)壓(ya)(ya)(ya)上下(xia)料(liao):通(tong)過工(gong)業機(ji)(ji)械手(shou)將產品從定(ding)位(wei)堆垛平臺(tai)(tai)移送到沖(chong)(chong)(chong)床壓(ya)(ya)(ya)力機(ji)(ji)模具中實施沖(chong)(chong)(chong)壓(ya)(ya)(ya),沖(chong)(chong)(chong)壓(ya)(ya)(ya)完成(cheng)后(hou)再通(tong)過機(ji)(ji)器人(ren)取料(liao)放入收料(liao)位(wei)置,實現單臺(tai)(tai)沖(chong)(chong)(chong)壓(ya)(ya)(ya)機(ji)(ji)械手(shou)集成(cheng)應(ying)用(yong);二(er)是(shi)機(ji)(ji)械手(shou)沖(chong)(chong)(chong)壓(ya)(ya)(ya)連線:是(shi)指多(duo)臺(tai)(tai)數控(kong)機(ji)(ji)床沖(chong)(chong)(chong)壓(ya)(ya)(ya)機(ji)(ji)使用(yong)多(duo)臺(tai)(tai)沖(chong)(chong)(chong)壓(ya)(ya)(ya)機(ji)(ji)械手(shou)之(zhi)間實現沖(chong)(chong)(chong)壓(ya)(ya)(ya)生產線連線。

3、鍛壓機床機器人集成應用

熱(re)模(mo)(mo)鍛(duan)(duan)生產(chan)線通常由兩臺(tai)模(mo)(mo)鍛(duan)(duan)壓(ya)(ya)機(ji)(ji)組(zu)成(cheng),成(cheng)型和切邊使用。熱(re)模(mo)(mo)鍛(duan)(duan)機(ji)(ji)器人集成(cheng)應用通常配置兩臺(tai)機(ji)(ji)器人,一(yi)臺(tai)將中頻爐處理后(hou)的高(gao)溫物料移送(song)給沖(chong)(chong)壓(ya)(ya)成(cheng)形模(mo)(mo)鍛(duan)(duan)壓(ya)(ya)機(ji)(ji),另外一(yi)臺(tai)取料放入模(mo)(mo)鍛(duan)(duan)壓(ya)(ya)機(ji)(ji)進行切邊。部分工序為防止高(gao)溫沖(chong)(chong)壓(ya)(ya)工件粘住模(mo)(mo)具,需要(yao)每(mei)次沖(chong)(chong)壓(ya)(ya)后(hou)對模(mo)(mo)具進行潤滑。

4、折(zhe)彎(wan)機(ji)床機(ji)器人集成應用

工(gong)(gong)(gong)業機(ji)器人配(pei)套折彎機(ji)集成應用主要(yao)的方式有:機(ji)器人配(pei)置(zhi)吸盤,上料分料機(ji)、定位臺、下料臺、翻轉(zhuan)架形(xing)成折彎單元。二是機(ji)器人與激光設備(bei)或數控沖床、工(gong)(gong)(gong)業機(ji)器人行走軸,板料傳輸線(xian),定位臺,夾具(ju)形(xing)成的柔(rou)性加工(gong)(gong)(gong)線(xian);通常是根據實際生(sheng)產情況(kuang)定制。

海智工業機器人當然除了以上的數控機床機械手集成應用外還有做很多機床機器人項目如:PCB上下料、切割機床上下料、CNC、成型機、銑床、磨床等數控機床,如果不是數控機床東莞海智也可以進行改造實現自動化生產。